Facilities

All users must be authorized by Professor Atieh Moridi prior to training taking place. All users must be trained and certified by a senior member in the laboratory. The lab policies and standard operation procedures are posted on the Lab’s Common folder on Box.

Shared Facilities at Cornell

We are users of many shared facilities at Cornell. Some are listed below. New users should follow instructions of each to get access.

Cornell Center for Materials Research (CCMR)

Cornell High Energy Synchrotron Source (CHESS)

*Interested in collaborating? Contact Prof. Atieh Moridi at moridi@cornell.edu

Click on the tool to learn more

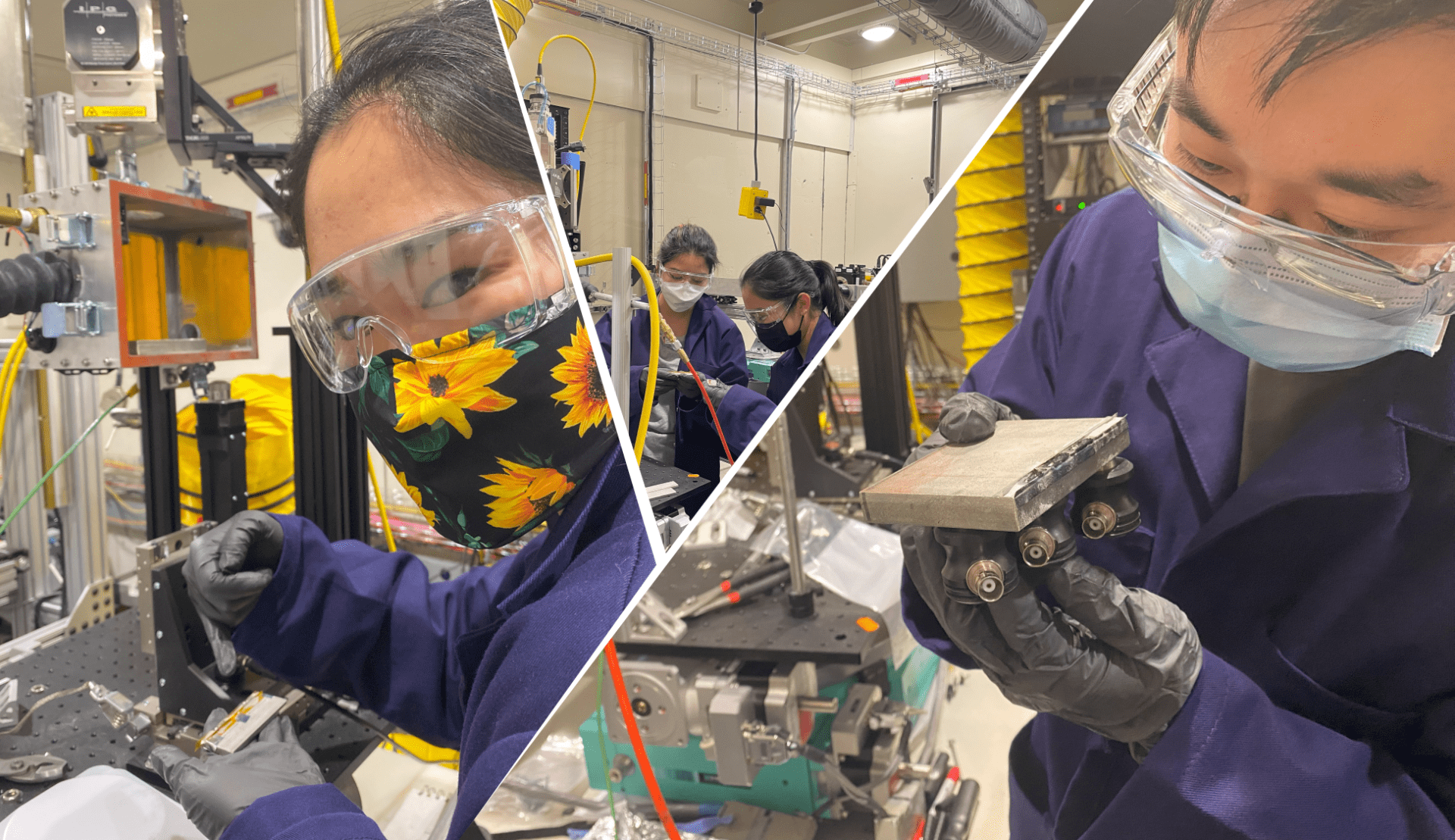

Customized synchrotron compatible AM Setup

L-DED & L-PBF in-situ set-up

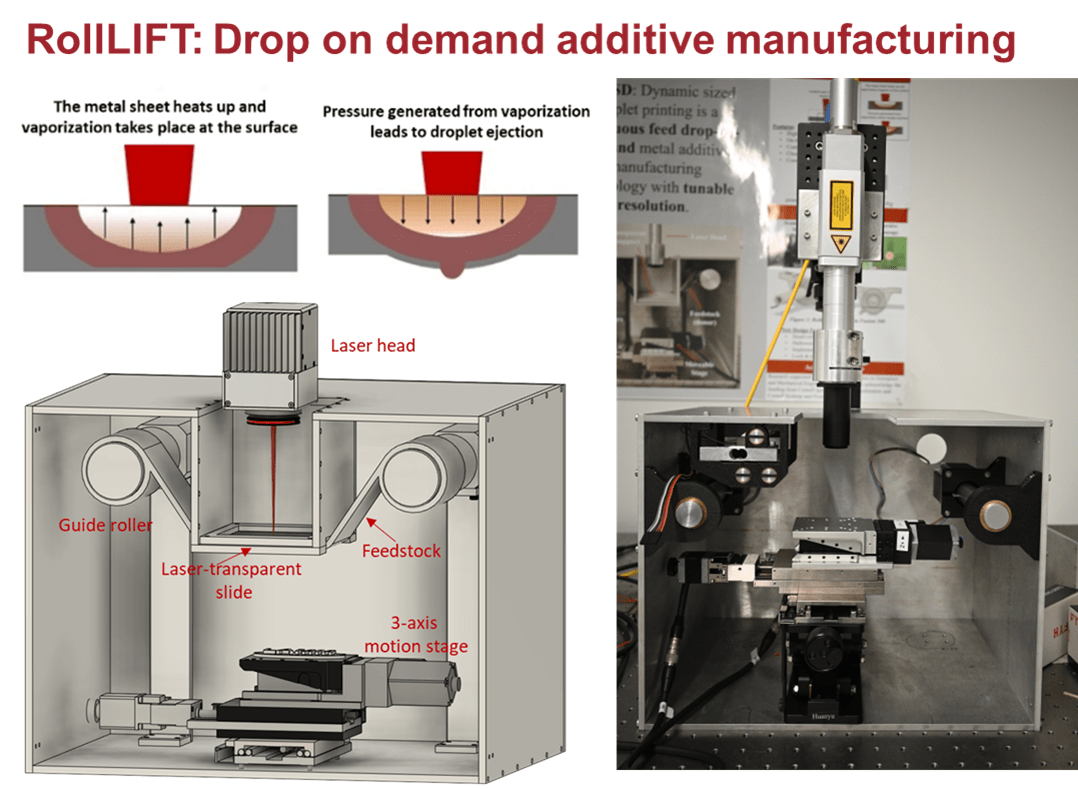

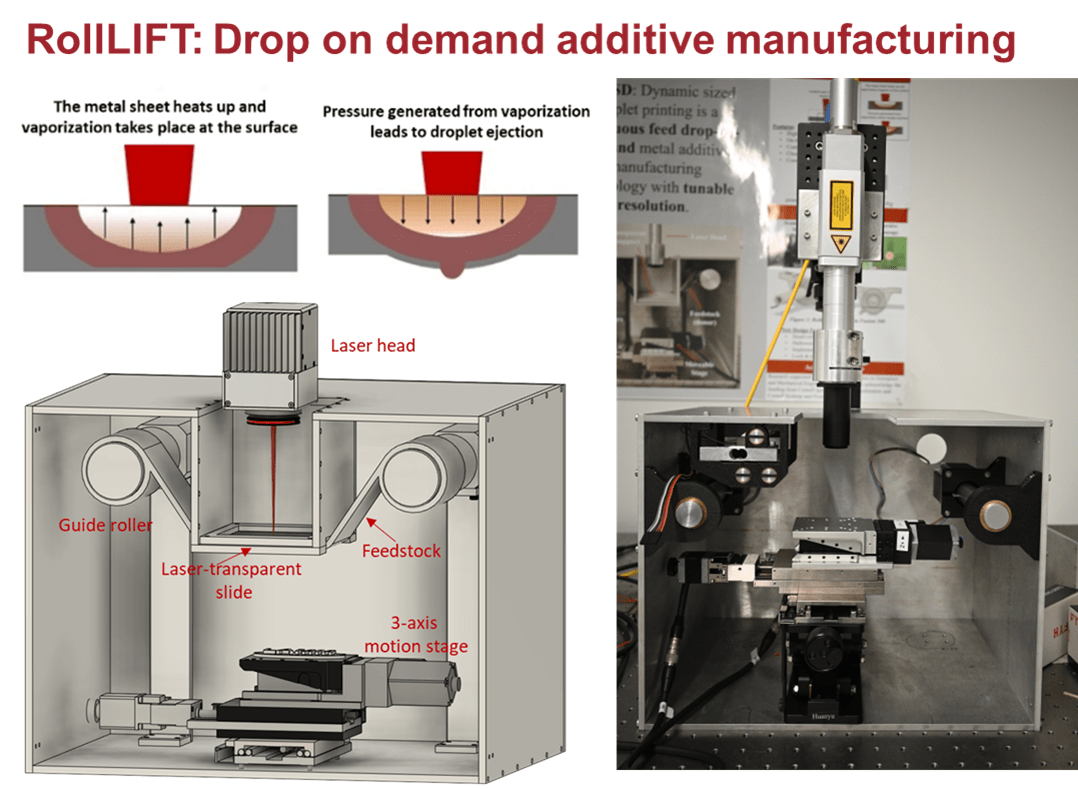

Drop on demand additive manufacturing

RollLIFT

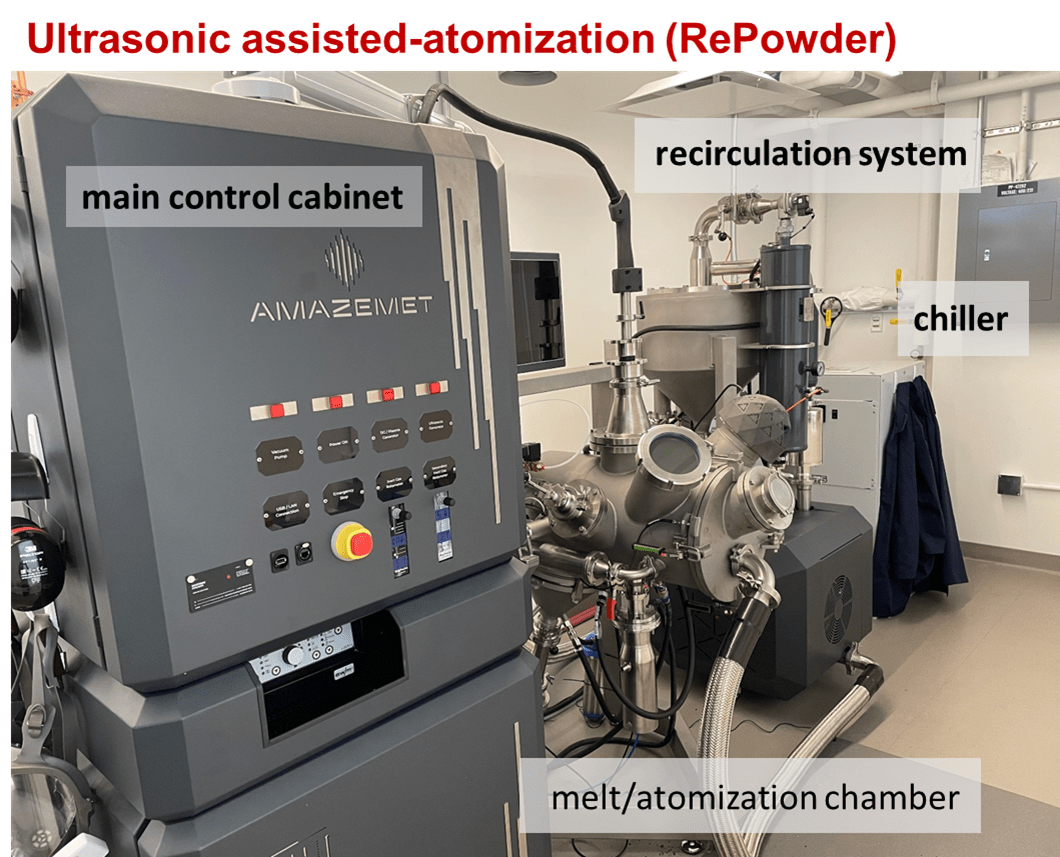

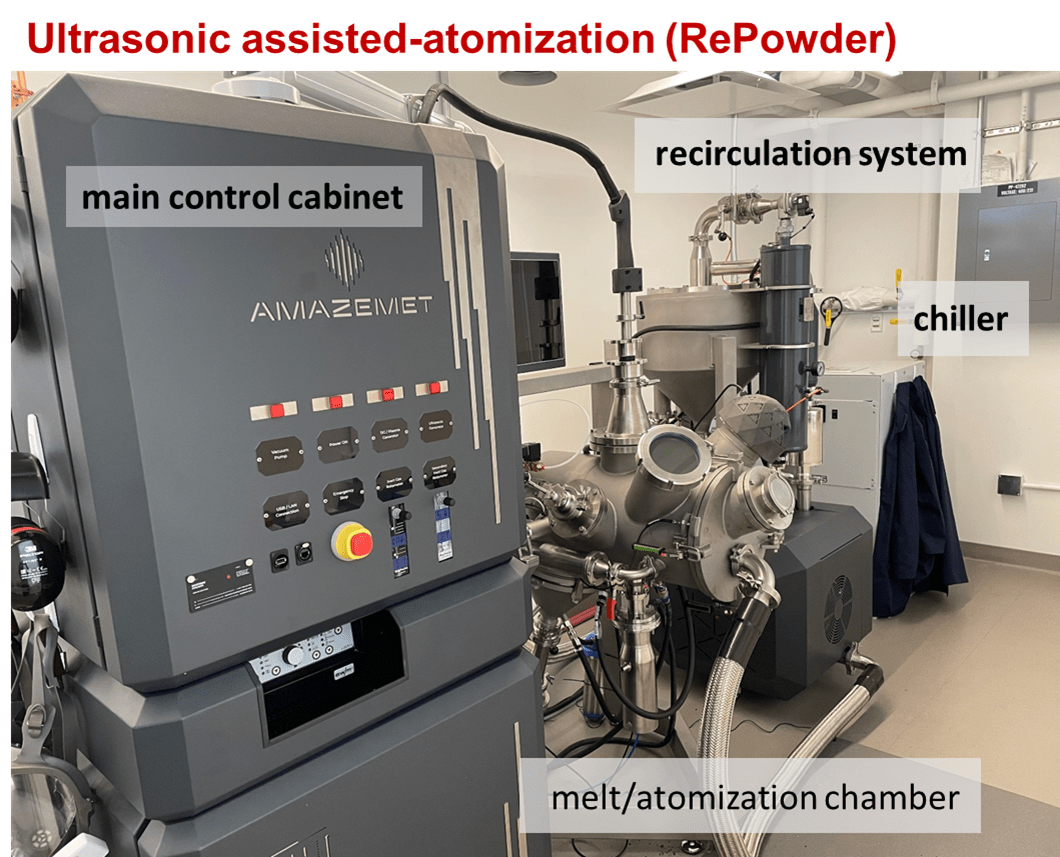

Ultrasonic assisted-melting and atomization

RePowder

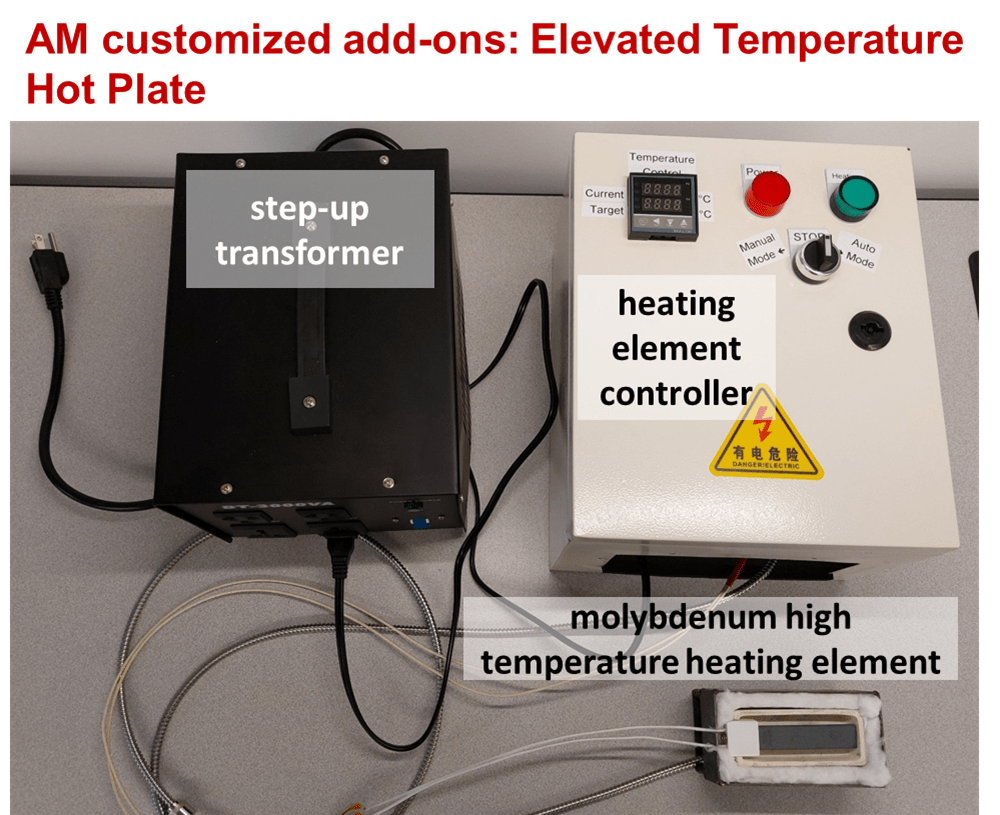

AM add-on: Elevated temperature hot plate

L-PBF and L-DED compatible

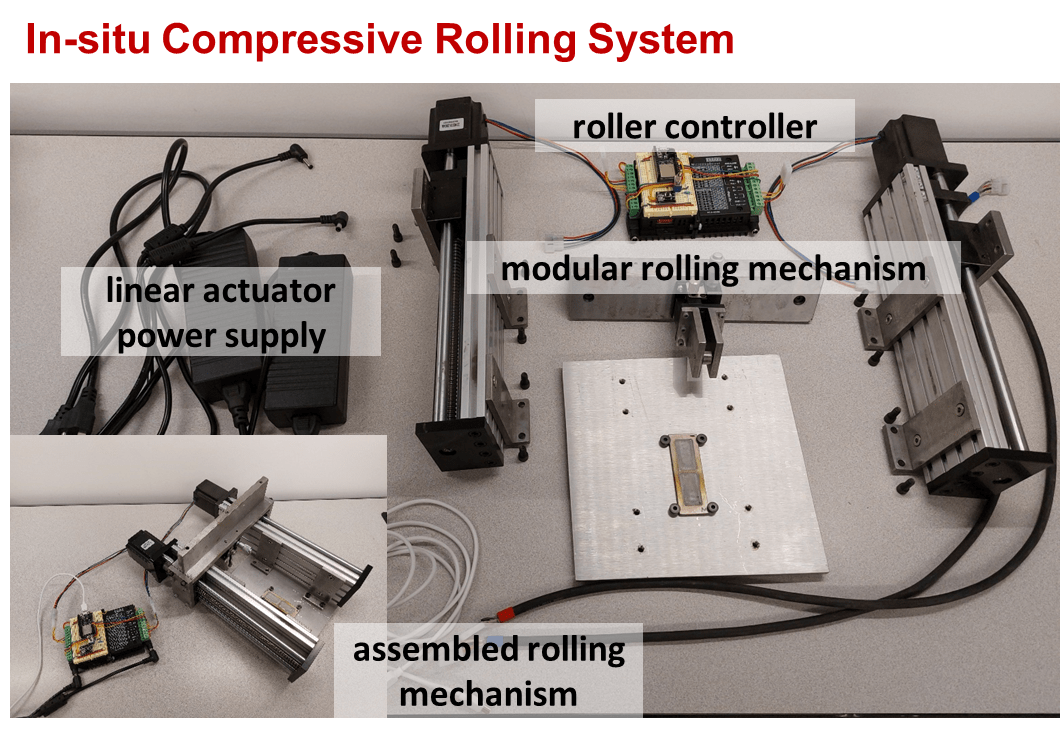

AM add-on: In-situ compressive rolling system

L-DED compatible

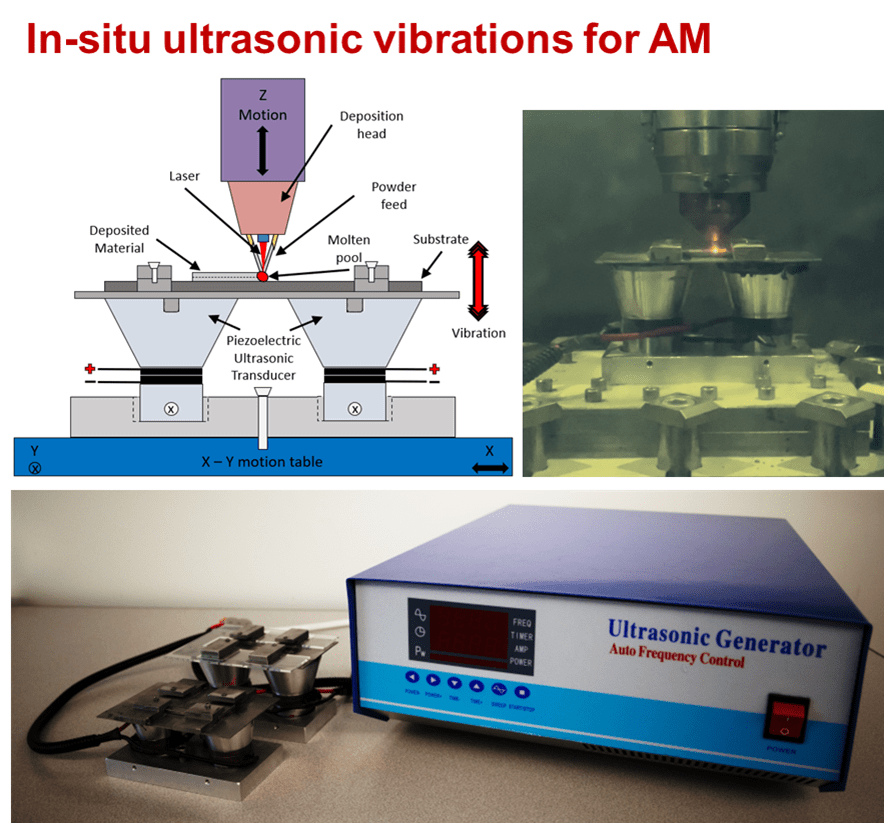

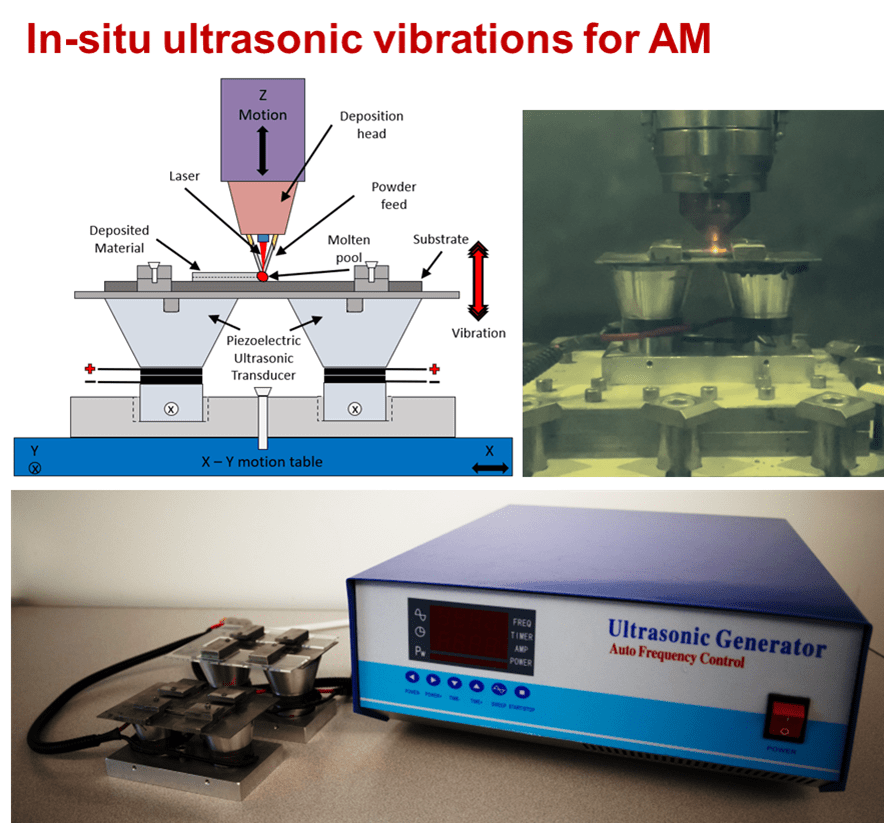

AM add-on: in-situ ultrasonic vibrations

L-DED compatible

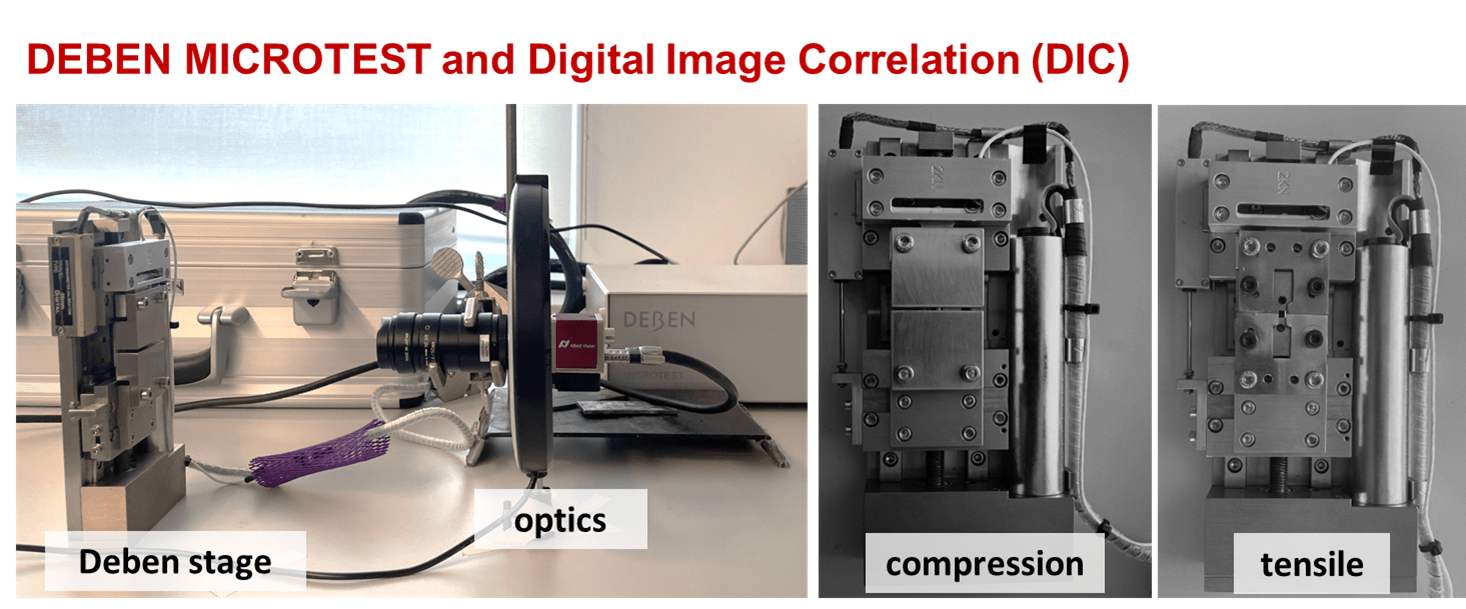

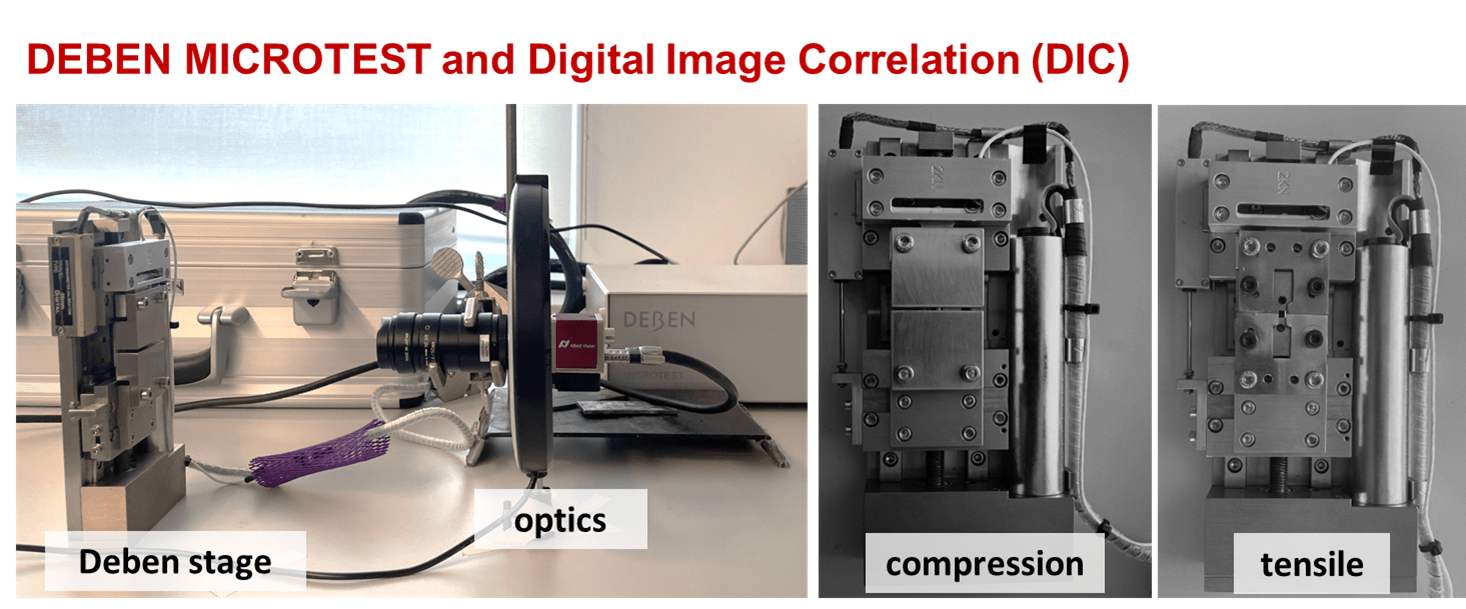

Micro tensile and compression tester

DEBEN stage

Tensile and compression modes

TEM sample preparation and imaging

TEM/STEM & FIB

Manufacturing & Processing

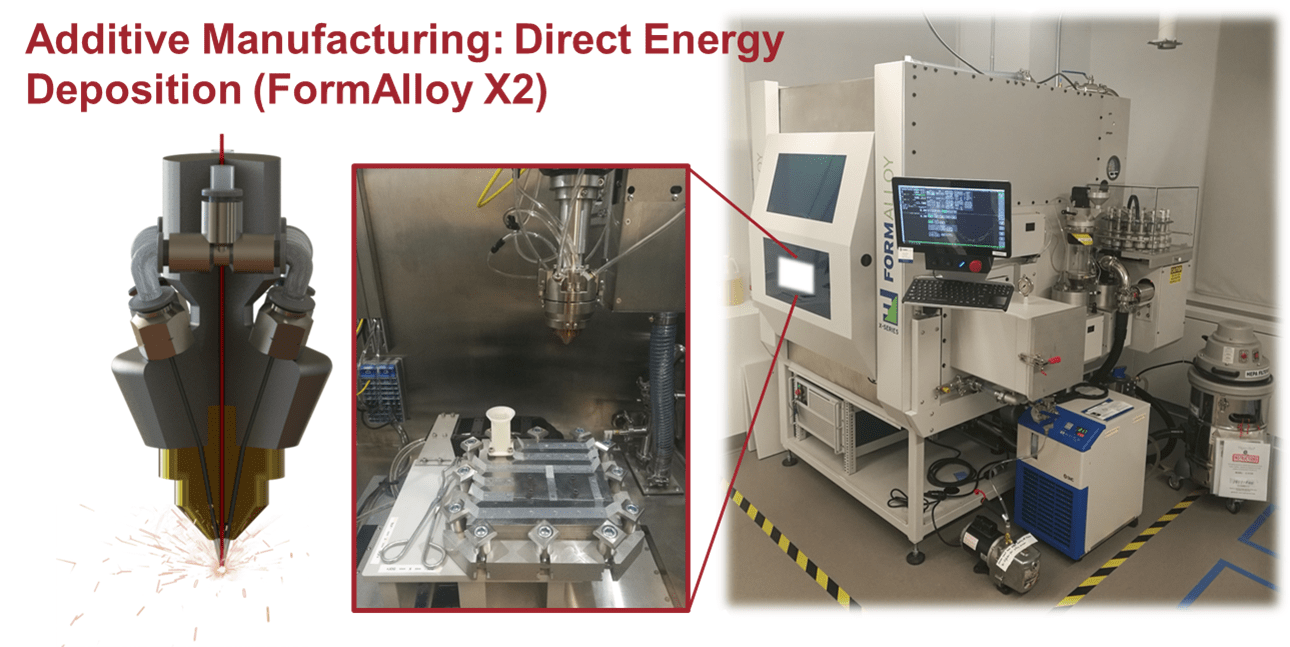

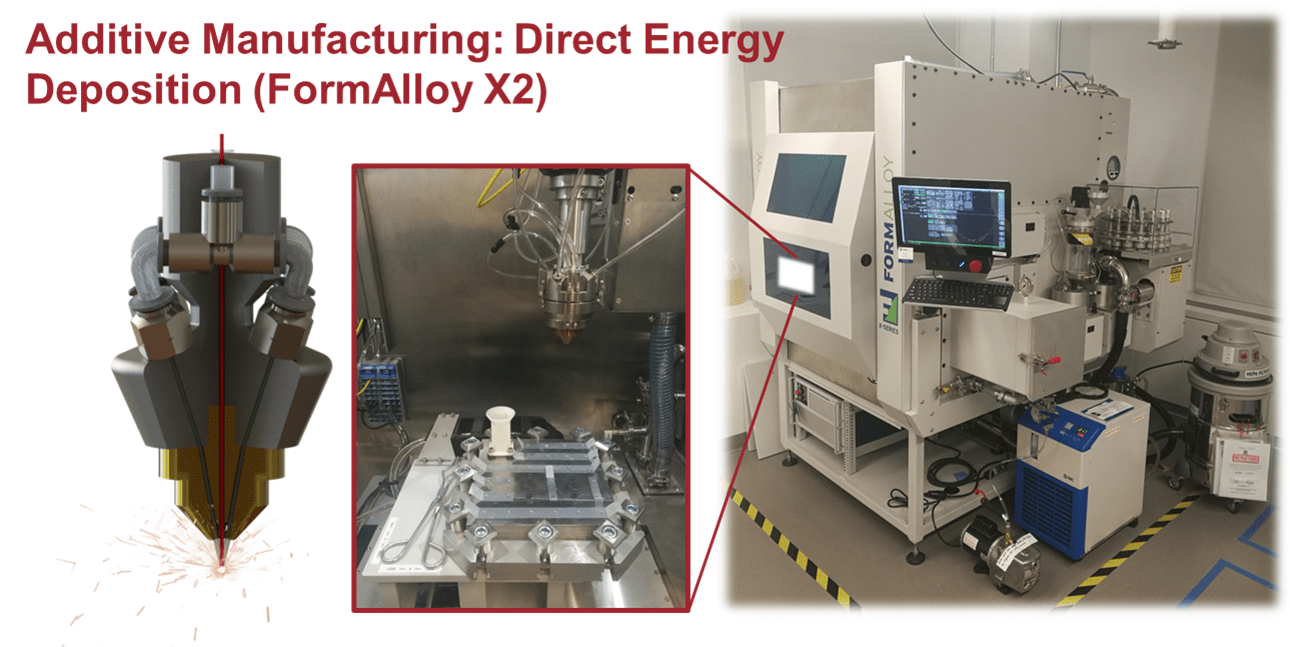

Direct Energy Deposition (FormAlloy X2)

Formalloy X2 is an industrial grade AM system under the branch of direct energy deposition (DED). It is a powder-based system that utilizes a powder delivery nozzle coaxial to the power source, a Nd:YAG laser with maximum output of 500W and a spot size of 1.2mm. Equipped with two powder feeders, the X2 can handle large scale prints on its print bed of 8in x 8in as well as sample fabrication using only a small amount of experimental materials. Its alloy development feeder (ADF) allows change of material mid-print, making it capable of printing gradient materials. The application of Formalloy X2 system in our lab is currently focused on material processability and microstructure studies, as well as fabrication of samples used for mechanical testing.

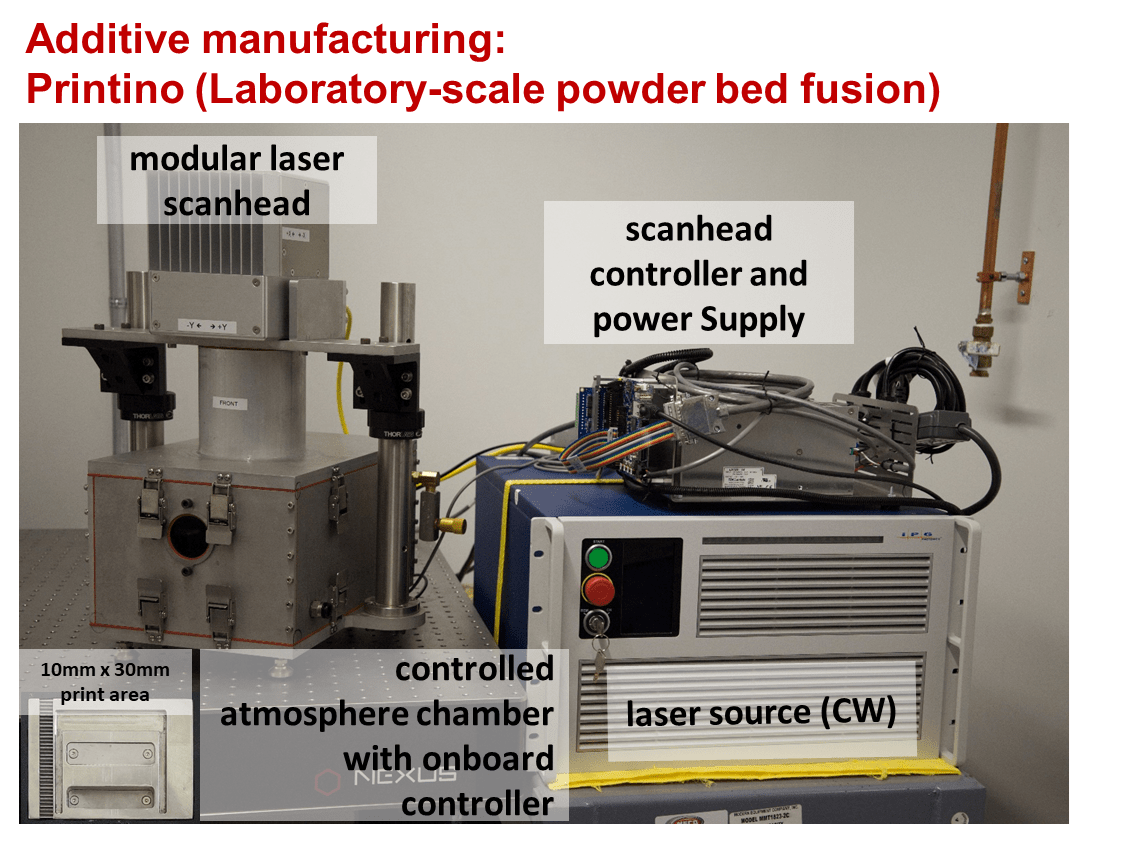

Laboratory-scale powder bed fusion (Printino)

Printino is created to provide a lower cost lab scale powder bed fusion metal additive printing testbed with high configurability for material testing. The design goal was to minimize feedstock use for test coupons’ production while keeping the cost down and enable some configurability as well. The system utilize a fiber laser source (interchangeable to achieve DED or PBF laser spot size), coupled with an off-the-shelf scanhead to selectively fuse powder within each layer. The layering of the power is achieved with a completely custom in-house built powder bed system enclosed in an inert atmosphere chamber. Control of the powder bed system is via a custom graphical user interface while the communication between powder bed and laser-scanhead combination is built into the on-board electronics in the powder bed system.

Customized synchrotron compatible AM Setup

The third generation CHESS AM setup can be operated in multiple modes to conduct simple AM experiments, specifically meant for synchrotron integration and performing single line scans in the lab. There are two unique capabilities: (i) DED with a laser spot size of 500 μm and speeds around 25 mm/s, with capability to print multiple layers with a powder feeding mechanism; (ii) PBF with a laser spot size down to 50 μm and speeds around 5000 mm/s with the galvo to print single layer prints. Currently, we have a multi-mode laser with a highest achievable power of 500 W, with the unique capability of setting the system in pulsed mode if desired (down to millisecond regimes). In the future, we will also have the option of a Gaussian laser.

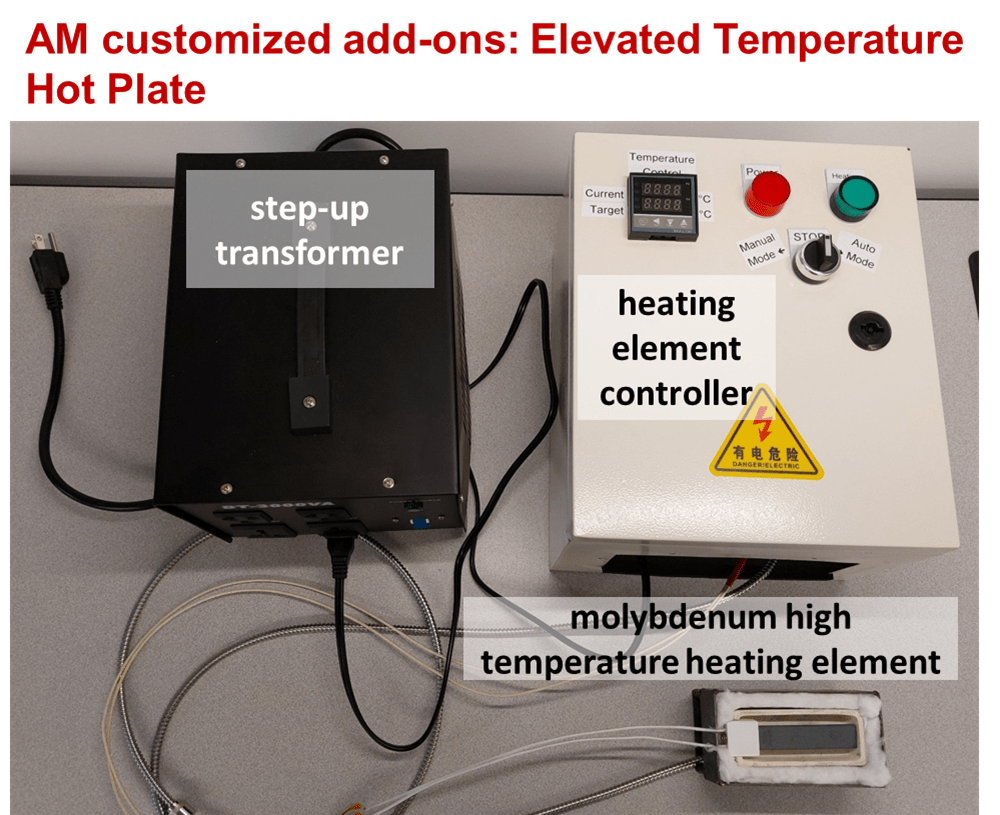

AM add-on: Elevated temperature hot plate

Custom hot plate designed to preheat substrate materials of hard-to-process materials during AM. These approach aims to limit the solidification cracking during the rapid cooling in AM. Preheating the substrate reduces the severe thermal gradient between the substrate and the deposited material, improving AM processibility. The molybdenum heating element, whose melting point is at 2,623 °C (4,753 °F) enables heating to reach temperatures up to 1000 °C. The system can be run either in manual mode (continuous heating) or automatic mode with a target temperature set.

Automatic mode, the heating element temperature is measured from its underside using a high temperature thermocouple and the system regulates the set temperature intermittently. The ceramic crucible and surrounding ceramic wool reduces thermal loss, the steel frame allows this system to be placed in small print chambers or be mounted on the build plate in our Formalloy X2 DED printer.

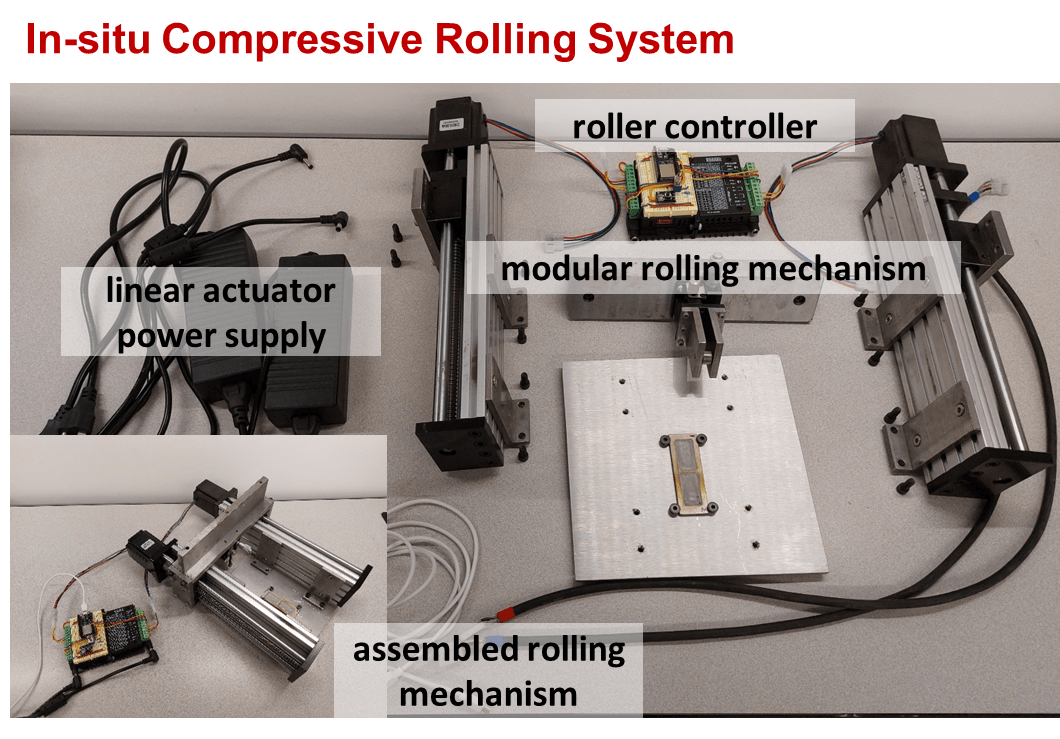

AM add-on: In-situ compressive rolling system

Custom in-situ rolling system designed to perform hot rolling during additive manufacturing (AM) to enhance the microstructure of the deposited material. The enhancement roots from the refined grain size as well as reduction of grain preferred orientation.

This system is built to work with our Formalloy X2 DED printer and has a modular design to facilitate transporting of the system in and out of the build chamber. The rolling step is performed right after a line print via a simply button trigger. It combines two stepper motor driven linear stages, a custom roller bridge structure, and a microcontroller. The construction of the roller bridge utilizes tool steel, which provides maximum amount of rigidity and prevent unwanted deflection during compressive rolling. The system can be configured easily into calibration mode/half layer compression mode or full layer compression mode.

AM add-on: in-situ ultrasonic vibrations

The customized set-up is composed of two transducers of 28kHz or 40kHz work together to apply ultrasonic vibrations to a thin sheet of metal on to which the substrate is mounted. The substrate is attached to the system using set screws to ensure that the substrate maintains contact with the system during the entire printing process. The transducers are connected to a ultrasonic generator. Currently, the system can be used with the FormAlloy X2 (DED) and the in-house built DED simulator used for synchrotron studies.

Ultrasonic assisted-melting and atomization (RePowder)

The rePowderTM system allows the atomization of custom metallic powders for an in-house rapid alloy prototyping. Composed of a main control cabinet (left), melt/atomization chamber (center), and recirculation system (right), the rePowderTM system takes elemental feedstock to first melt into a homogeneous mixture of desired composition using a plasma torch, a transducer and sonotrode to ultrasonically atomize into fine, spherical powders.

Powder particle sizes can be controlled using various frequencies on the sonotrode, ranging from L-PBF (15-45 microns) to DED (45-150 microns) size ranges

Drop on demand additive manufacturing (RollLIFT)

RollLift is a custom-built laboratory scale drop-on-demand system for micron scale additive manufacturing. It has a continuously fed roll-to-roll foil-based system that works in conjunction with a ns-pulsed laser system with a maximum output of 220 W and a spot size of 28 µm .

The laser can provide four distinct pulse durations :30, 60,120, 240 ns. The system contains a set of stepper motors that are used for the continuous feed and a 3-axis motion stage for moving the build platform.

Material Characterization

Micro tensile and compression tester (DEBEN stage)

The DEBEN MICROTEST Controller has a 2kN stage for real time observation of high stress regions on a sample (max: 50mm x 15mm x 10mm) during tensile or compression (cyclic or constant) testing with an optical microscope. The DEBEN Software sets the drive parameters and displays the stress/strain curve, time, and extension live on the computer screen.

We pair this with Digital Image Correlation (DIC), using the GOM Correlate Software to visualize these deformed regions and to extract measurements such as strain values and rates.

TEM sample preparation and imaging (TEM/STEM & FIB)

Sample prep via FIB: The Helios G4 UX Focused Ion Beam (FIB) has a dual beam technology: electron and ion column for versatile and capable FIB milling. The electron column enables high resolution secondary and backscattered imaging even at low voltages. The Ion Column with Fast Beam Blanker enables high resolution imaging and milling at high voltages, well down to low voltages. Such low voltages are critical for the production of high-quality lamella with minimal damage layers for transmission electron microscopy (TEM). Additionally, the beam currents now extend three times higher than previously available, enabling milling of samples not previously possible due to realistic time constraints.

Training and access to the tool is provided by CCMR (https://www.ccmr.cornell.edu/instruments/thermo-fisher-helios-g4-ux-focused-ion-beam/)

Sample Imaging TEM/STEM: The FEI CryoS/TEM is the first monochromated, high-resolution cryo-S/TEM of its kind. This instrument is capable of imaging inorganic and organic materials at the nanoscale. It is equipped with a Field Emission Gun (X-FEG), a monochromator, probe corrector (STEM) and the availability of single and double tilt holders for room temperature and cryo work. The microscope is set up for data collection at 60, 80, 120, and 300 kV providing resolutions of up to 0.08 nm.

Available modes for data acquisition include: TEM, cryoTEM, cryo tomography, Bright Field/Dark Field TEM/STEM, EELS, STEM, Lorentz TEM/STEM, and Low Dose imaging

Request training and access through CCMR tool manger: https://www.ccmr.cornell.edu/instruments/fei-cryo-stem/